Except for their large and complex equipment and products, BEL India develops and produces components, devices, and parts for their top products. In this article, we will go over seven of these and explore what they are for.

Table of Contents

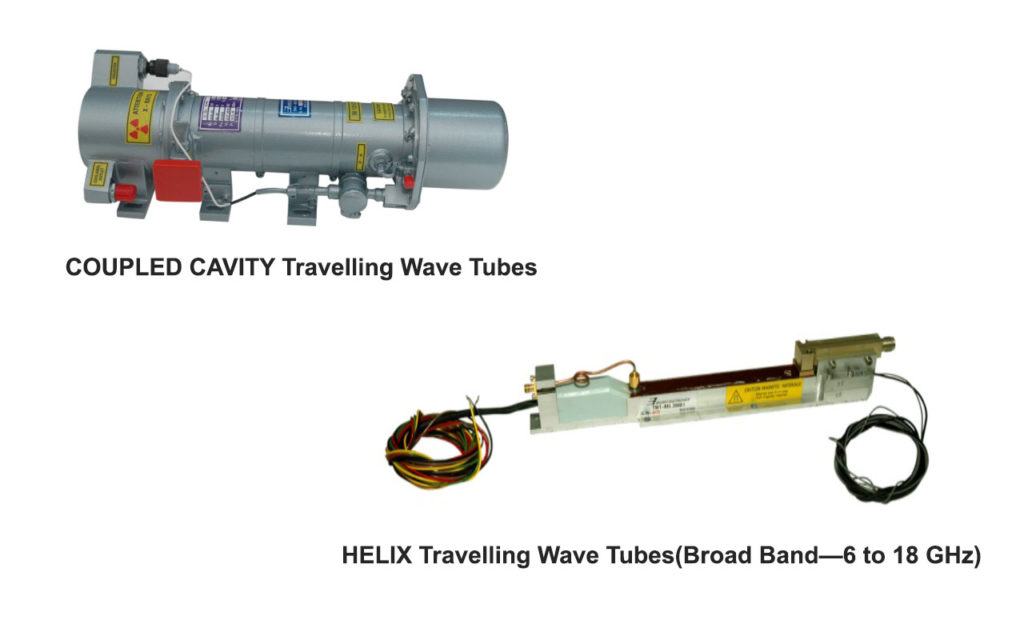

1. Microwave Tubes

source: bel-india.in

BEL India produces two types of microwave tubes:

Coupled Cavity Travelling Wave Tubes and Helix Travelling Wave Tubes (Broad Band—6 to 18 GHz)

2. Microwave Super Components

These products are designed and manufactured for radar and electronic surveillance applications. They include:

Medium power microwave solid-state power amplifiers, exciters, receivers and frequency converters, power combiners, power samplers and detectors, solid state switches, low and high power filters, control elements like limiters, variable attenuators, phase shifters, DLVAs, and directional couplers, frequency sources of up to 40GHz, transmit and receive modules, and superhet and homodyne receivers, multichannel IF receivers.

Technologies that these devices employ are based in:

LTCC, MICs, MMICs, GaAs, SiGe, GaN, LDMOS, SMD, SMT, Die, Teflon RF/MW PCBs, multi-layer PCBs, RF and High-Speed PCB design, microstrip, stripline, suspended substrate techniques, FPGA designs for synthesizer programming, and RF/IF processing using digital techniques.

3. Microwave Power Module (MPM)

source: bel-india.in

The Microwave Power Module is made of a helix miniature traveling wave tube, or a micro TWT, a solid-state driver amplifier (SSA), and an electronic power conditioner. They are combined into one compact package that forms this power module.

The MPM is a low noise, compact, high-efficient and wideband RF amplifier mainly for naval applications. This MPM is able to operate in an array of different conditions to generate high power RF output for a multi-beam jammer. It also contains a TWT, as well as a power supply within a single water-cooled package.

The nomenclature is microwave power module, the minimal power output is 100 W pulsed and CW, input voltage of 270 VDC, and it weighs a maximum of 4Kg.

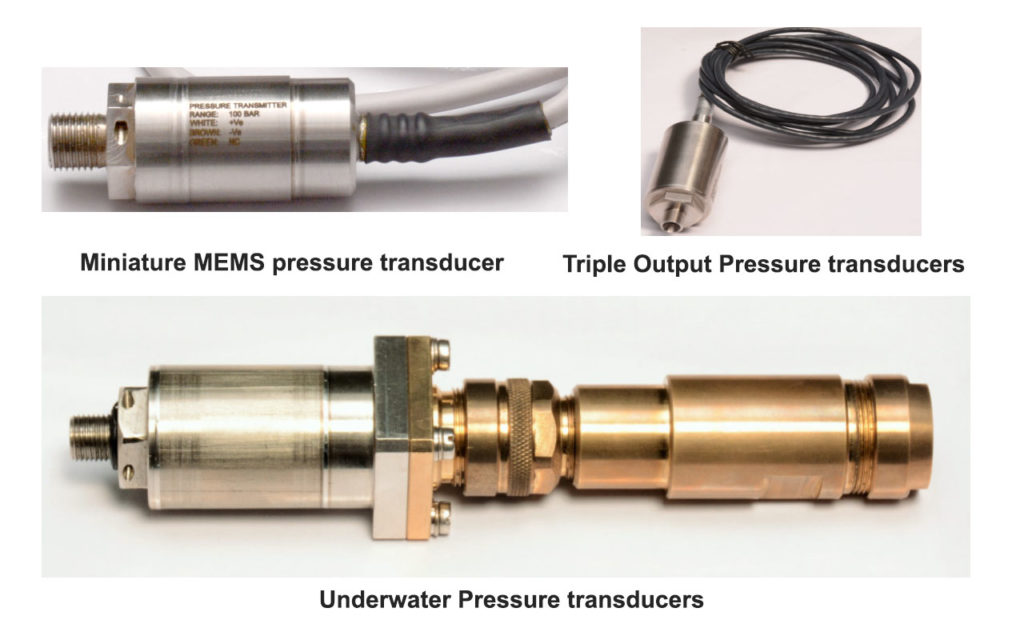

4. Pressure Transducers (PT)

These devices include:

Miniature MEMS pressure transducer, triple output pressure transducers, and underwater pressure transducers.

MEMS pressure transducers are indigenously designed and manufactured at BEL India state of the art facilities. They are qualified with defense and aerospace standards and developed specifically to meet customer requirements. The operating pressures of PTs range from 10 to 400 bars.

5. Conductivity Temperature and Depth (CTD) Sensor

CTD sensors are indigenously developed and manufactured at BEL India facilities and are used for measuring storing conductivity, depth and temperature data. CTD has excellent accuracy, which is less than 0.5% for depth, less than 0.02% for conductivity, and less than 0.05 C for temperature data. These sensors are used in submarines and other underwater situations.

6. Depth Sensor

Designed and developed by BEL, these high accuracy MEMS pressure transducers are used in the measurement of depth in SONAR systems. They are developed with complicated mechanical assembly and signal conditioning electronics and can withstand water pressures of below 1000 meters of depth.

7. Digital Multichannel Data Recorder – 16A (DMR-16A)

This system is designed with high-end microcontrollers, FPGA incorporating advanced signal processing techniques, embedded firmware, and necessary user interface application software. The main focus is on the enhanced system performance, reliability, and maintainability.

Features of this device include:

Simultaneous recording of user-selected analog audio channels with a maximum of 16 channels, user operation, control and monitoring of equipment from remotely connected client terminals, live audio data streaming under monitoring in the equipment, as well as over Ethernet, into the remotely connected client terminal simultaneously, and SSD based storage with data compression.

Furthermore, the user interfaces through runs through a capacitive touch keypad and a TFT LCD display, along with a touch screen. It is compliant with EMI and EMC standards of MIL-STD 461E, and environmental test standards of JSS55555: Class-N1.

There is an auto-start fiction with last recording configuration, fault detection, fault localization and maintenance support, and an architecture that is modular to facilitate upgrades of hardware and software. The data recorder can also be customized for other more specific requirements.